Kymene wet-strength additives comprise a family of products proven to significantly improve the wet strength of paper. Kymene additives have been trusted by papermakers for more than 65 years. And, thanks to our ambitious R&D program, they’ve only improved with time.

Commercial applications confirm that Kymene wet-strength additives provide a number of value-added benefits:

- Improved wet strength

- Improved retention and drainage

- Enhanced creping control

- Improved dry strength

- Reduced chemical costs

- Improved machine runnability

|

Feature |

Benefit |

|

A legacy of innovation |

The most complete line of wet strength resins on the market, making it possible to address a full range of customer compliance needs while balancing cost-in-use. |

|

Advanced chemical techniques and manufacturing processes |

Introduction of high-solids, high-efficiency resins with ever-increasing levels of azetidinium (AZE) functionality. |

|

Biodehalogenation and membrane separation technologies |

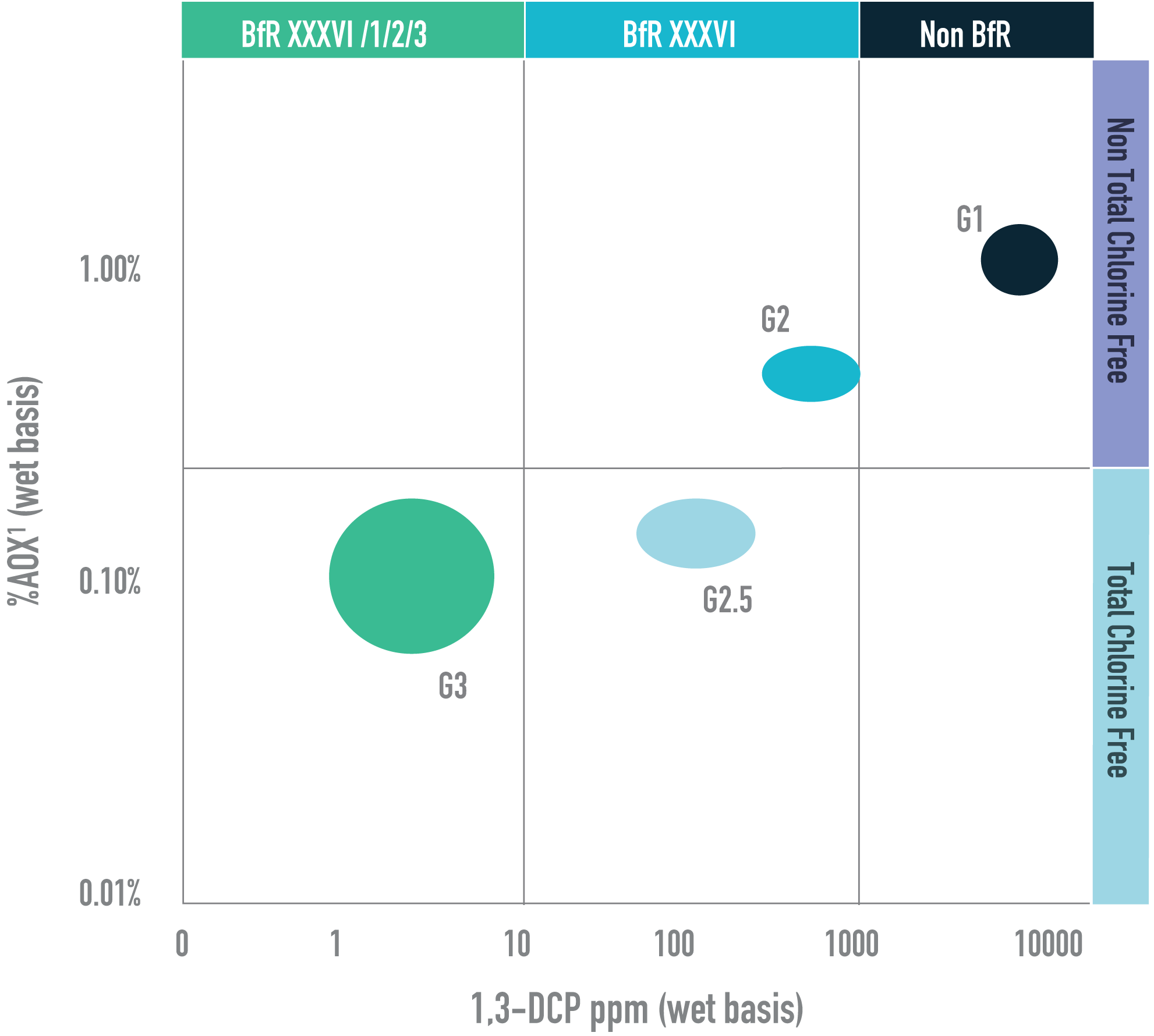

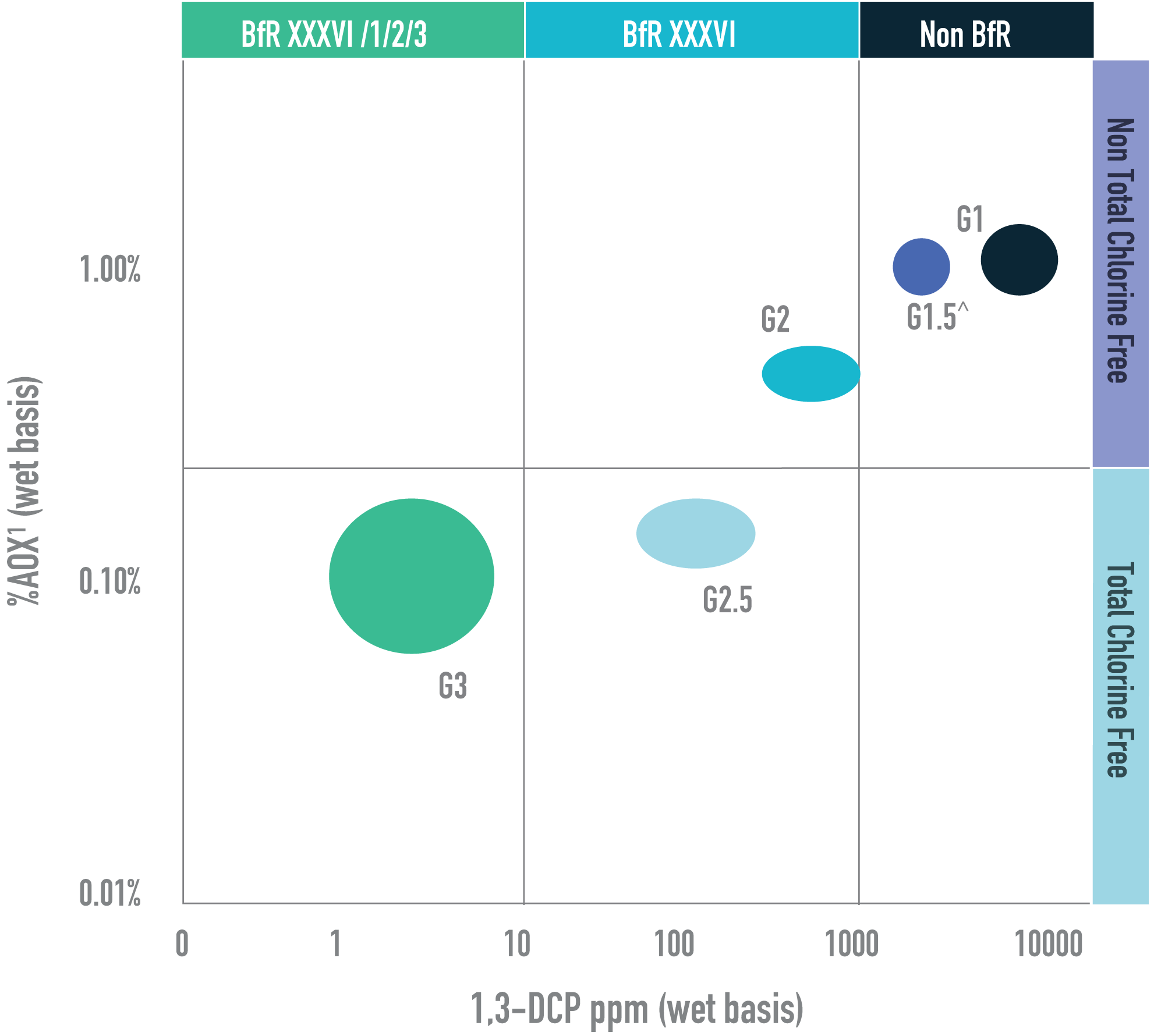

Stronger-performing resins with reduced levels of 1,3-DCP and 3-MCPD, as well as aminochlorohydrin and polymer-bound CPD. |

|

Extensive manufacturing footprint |

Ability to provide wet-strength resins efficiently and cost-effectively to any mill, anywhere in the world. |

|

Dedicated R&D organization and wet-strength resin expertise |

Commitment to deliver the next generation of wet-strength resins that increase solids, improve functionality, and remain far ahead of all regulatory compliance issues. |

Technology Overview

Kymene wet-strength additives, based on polyamide-epichlorohydrin (PAE) resin chemistry, help papermakers improve the wet strength of grades intended primarily for the consumer market. These grades include tissue (facial, kitchen towel, wipers, napkins and tableware), packaging (liquid packaging, aseptic container, carrier board, and other forms of food packaging), and specialty (tea bag, coffee filter, labels, currency, laminating grades, etc.).

Designed to be used at neutral-to-alkaline pH, PAE resins have a high level of wet-strength permanence, help improve machine efficiency and do not adversely affect paper absorbency as do some other chemistries.

Solenis has developed methods, including post-synthesis technologies, to modify the basic chemistry of Kymene wet-strength resins to make them stronger-performing while reducing the by-products 1,3-dichloropropanol (1,3-DCP) and 3-monochloropropan-1,2-diol (3-MCPD), as well as aminochlorohydrin (ACH) and polymer-bound CPD (PB-CPD) for our customers’ paper and board regulatory compliance needs.

How They Work

Kymene wet-strength additives are water-soluble polymer products. The most commonly used solutions are formulated with polyamide-epichlorohydrin (PAE) resin chemistry resin chemistry and are intended primarily for paper products for the consumer market. PAE resins function in neutral/alkaline papermaking processes. They have a high level of wet-strength permanence, help improve machine efficiency and do not adversely affect paper absorbency.

Kymene additives work during the curing process, when the functional groups on the Kymene polymer react with cellulose fiber to form a covalent bond. The polymer molecules cross-link, forming a network in the cellulose web that provides strength when the paper becomes wet. Kymene wet-strength products can also reinforce existing fiber-to-fiber bonds, which further enhance the strength of the paper.

For even greater paper performance, Hercobond™ dry strength additives can be used with Kymene wet-strength additives. This combination can increase wet and dry tensile performance by as much as 25 percent.

Today, Solenis offers the broadest portfolio of wet-strength resins in the world. We provide Kymene wet-strength additives in a wide range of solids content to ensure the perfect fit for your needs. Our portfolio can help you balance freight costs, shelf life and product stability concerns.