Innovative chemistries, advanced monitoring and control systems, and expert support for your food & beverage challenges.

The Diversey Divos™ product portfolio, cleaning procedures, and application expertise deliver superior results, increasing performance and processing efficiency for all membrane installations (MF, UF, NF, RO, Electrodialysis) in the food, beverage, dairy, and pharmaceutical industries.

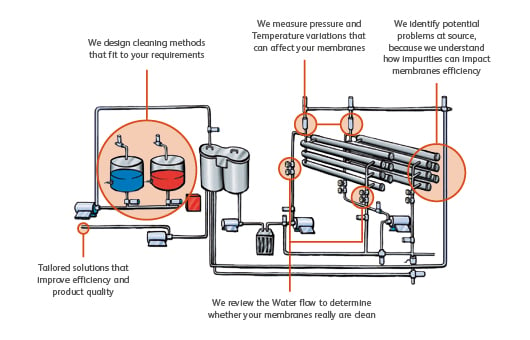

We provide customized programs that minimize cleaning times, lowering water, energy, and other utility usages, while maximizing processing capacity and productivity.

Our representatives and application specialists will work closely with your managers and operators during auditing to understand your process and provide the best solution to meet your exact needs.

Comprehensive on-site support and training during start-up and ongoing service, such as regular reviews and superior troubleshooting capability, ensure effective cost management and problem-free production is maintained.

When used in combination with the correct maintenance regime and processing procedure, our customized cleaning programs ensure maximum process capacity and productivity while extending the life of your membrane.

Products

Through our extensive portfolio, our partners have access to chemicals, equipment, knowledge-based services (KBS) and training solutions, all backed by decades of global experience.

An in-depth analysis service for F&B CIP systems. Includes hygienic design and cleaning chemistry evaluation for food safety effectiveness and CIP optimization.

Learn MoreBlog Article

Care needs to be taken during membrane cleaning to avoid damage such as stress-cracking the polymeric membrane layer.

Blog Article

[ON-DEMAND WEBINAR] We will explain what a Biofilm is and provide guidelines for prevention and removal.

The Diversey team offers the right people, technology and expertise to solve your most complex food and beverage challenges.