Innovative chemistries, advanced monitoring and control systems, and expert support for your food & beverage challenges.

We have a full range of open plant cleaning equipment to deliver optimum distribution, dilution and application of foam detergents, disinfectants and rinsing around your facility. Our solutions have been hygienically designed and can be selected to satisfy specific site and budget requirements.

All-in-One Mobile OPC Units

The Voyager enables foam application disinfection and rinsing of large areas from one unit. Options include two-person working capacity and an inbuilt air compressor.

Portable Foam Units

Our air-powered portable foam units have been ergonomically designed for ease of use.

Hand-Held Sprayers

Manual Centralized and Decentralized OPC Equipment

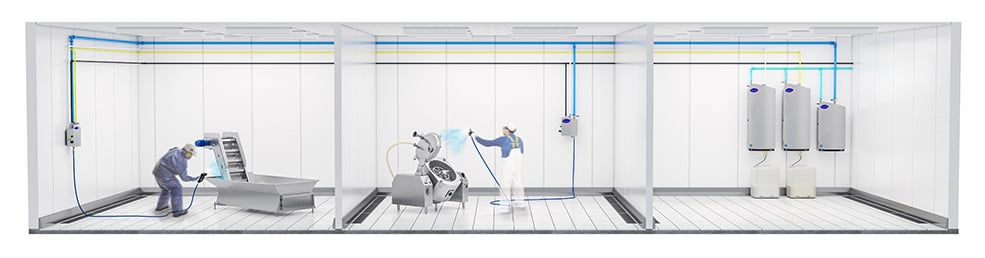

Manual centralized OPC is optimal for plants where concentrated chemicals are not allowed inside the process rooms. In a centralized configuration, all chemicals are pre-diluted in a separate, isolated chemical room and distributed through a series of pipelines. In the chemicals room, the rinsing water pressure is boosted by means of a multi-stage pump. Each satellite OPC unit will receive pre-diluted cleaning foam, pre-diluted sanitizer, and boosted pressure water.

Manual decentralized OPC is a cost-efficient solution, suitable for plants and processes where it is possible to have concentrated chemical jerrycan at the bottom of each satellite unit. In this configuration, plants have a single water booster unit distributing boosted water to each satellite. The chemical (cleaning foam and sanitizer) is diluted on-site, introduced and dosed by means of a venturi.

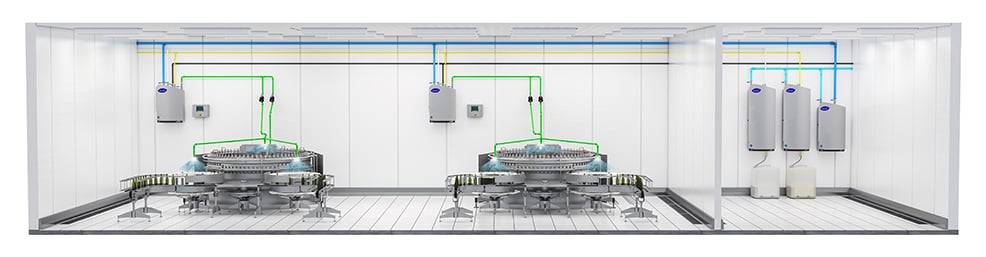

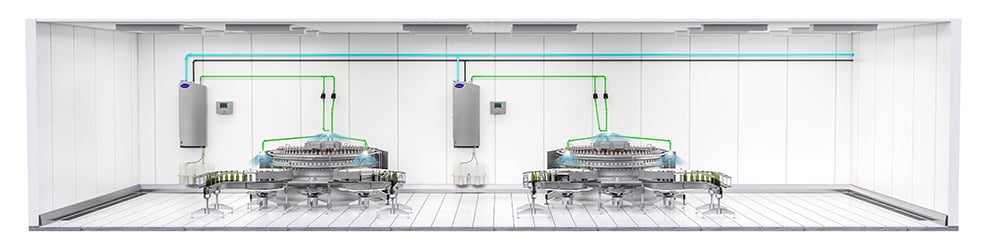

Automated Centralized and Decentralized OPC Equipment

Automated OPC systems are suitable for cleaning and sanitizing large production facilities that have complex, moving productions units, such as carousel fillers, belt conveyor, tipping conveyors, spiral freezers, spiral chillers, seasoning drums, tumbler trimmers among many other pieces of equipment. In an automated OPC installation, the cleaning foam and sanitizer is applied by means of a custom manifold, made to fit and reach each piece of equipment, ensuring that even the hardest-to-reach spots are covered during the cleaning and sanitation process.

During automated OPC, all pre-rinse, product application, contact, and post-rinse times are all controlled by a PLC, ensuring consistent and accurate results during each cleaning event.

Products

Through our extensive portfolio, our partners have access to chemicals, equipment, knowledge-based services (KBS) and training solutions, all backed by decades of global experience.

An in-depth analysis service for F&B OPC processes. Includes cleaning chemistry effectiveness, managing allergens and identifying bad habits of manual operators.

Learn MoreBlog Article

Learn how to identify common soils such as proteins, mineral deposits, fats and natural oils and how to remove them to ensure there is no risk of contamination.

Blog Article

[ON-DEMAND WEBINAR] Hear from our experts as they focus on answering questions about training and e-Learning submitted by the audience.

The Diversey team offers the right people, technology and expertise to solve your most complex food and beverage challenges.