Meet your challenges head on with our proven solutions.

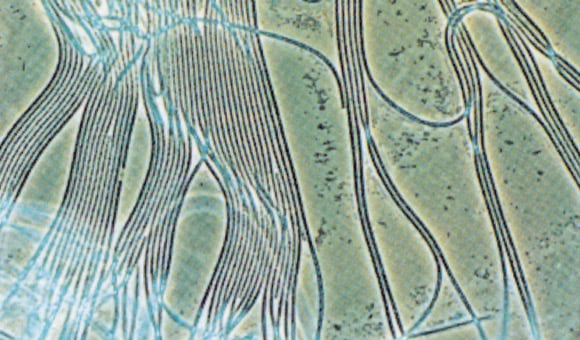

Microorganisms can cause numerous problems in aqueous systems, including slime deposits, microbiologically induced corrosion, unpleasant odors and hazardous gases. Likewise, they can cause raw materials to spoil and impact the quality of a finished product.

Solenis offers a variety of broad-spectrum, water-dispersible microbiological control agents, including oxidizing biocides and non-oxidizing biocides, that inhibit microbial growth in industrial processes and prevent additive spoilage.

Our non-oxidizing biocides include standard active products and proprietary blends, and our oxidizing biocides include conventional technologies, such as hypobromous acid and hydantoins, as well as novel technologies that dramatically reduce microbiological activity without any of the adverse side effects associated with strong oxidizing biocides.

Regardless of the type of product employed, our microbiological control programs are designed with careful consideration given to safe handling and operation and utilize state-of-the-art chemical feed systems with advanced monitoring and control capabilities.