Biofilm is usually defined as a loose matrix of many kinds of microorganisms — bacteria, fungi, algae, yeasts and protozoa — that is held together with a slimy substance called extracellular polysaccharide (EPS). Biofilms form in moist environments, where free-floating bacteria settle and then adhere to a surface. Once they are sessile, the bacteria begin developing a complex three-dimensional community that increases the survivability of the individual organisms in the community because of their communal existence. Biofilms form on a wide variety of surfaces, including metals, plastics, even plant and animal tissues. Once they become established, they can be difficult to remove and often lead to a number of serious issues, especially in industrial environments. As a result, biofilms cost billions of dollars every year in energy losses, equipment damage and product contamination.

The presence of biofilm on heat transfer surfaces poses a significant challenge to industrial operations. Biofilm can lead to decreased efficiency and microbiological-influenced corrosion under the biofilm. This can reduce the heat exchanger’s performance, or worse, lead to its failure. The rate of biofilm accumulation is quite fast, with deposits forming within a few hours. For this reason, proactive monitoring in the early stages of biofilm development increases the chances for a successful control strategy.

Turning on the Heat

Over the years, researchers have used several types of sensors to measure different characteristics of a biofilm as it grows. Some measure electrical resistance. Others measure thermal transmittance or piezoelectricity. Unfortunately, many of these available techniques measure biofilm growth using indirect parameters. For example, measuring carbon dioxide production or oxygen utilization provides an indication of biofilm growth, but it is not a direct measure of the biofilm itself.

The OnGuard™ 3B analyzer employs an ultrasound sidestream device that provides a direct measurement of biofilm. The device consists of two parts — a patented ultrasonic sensor and a target assembly made of metal. To ensure optimal conditions for biofilm growth, the metal surface is heated up to a given temperature range, usually 35–40°C.

Higher surface temperatures speed up microbial growth cycles and enhance colonization with higher bio-volumes, higher percent moisture and higher ratios of anaerobic to aerobic bacteria. The built-in variable heating element provides consistent heat output to maintain the desired surface temperature, while built-in thermocouples measure temperature differences in real time. With the assistance of a pre-programmed algorithm, the heat transfer reduction sensor also reports the development of biofilm as a fouling factor and a heat transfer reduction index. Figure 1 shows examples of the OnGuard 3B analyzer’s heated surface at an initial (clean) condition and after the biofilm growth.

Figure 1 – OnGuard™ 3B heated surface shows biofilm growth.

At the same time, the flowrate in the sidestream device is adjusted to have the best velocity conditions (i.e., lower velocity) to encourage biofilm to attach on the heated surface. It is recommended to apply 15 liters per minute.

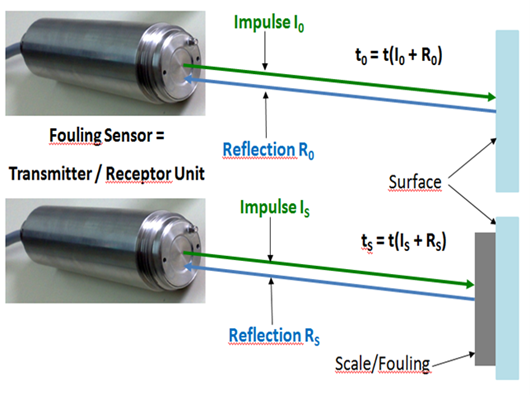

Configured this way in the sidestream environment, the OnGuard™ 3B analyzer is ready to measure biofilm. Here’s how it works: the device emits an ultrasound pulse toward the assembly surface. The pulse strikes the surface, and the echo returns to the sensor. Using the speed of sound in water and the time it takes for the reflected wave to return to the sensor, it’s possible to detect biofilm accumulating on the assembly surface. As the biofilm thickens, the time it takes for the echo to return to the sensor decreases (see Figure 2).

Figure 2 – OnGuard™ 3B sensor biofilm thickness measurement technique.

Real-Time, Revolutionary Biofilm Monitoring

The OnGuard 3B analyzer can mimic critical heat exchanger conditions in real time. The device duplicates the shear stress and heat input so that the fouling factor can be measured continuously and can be compared to the design and operating conditions of any heat exchanger of interest. The device measures not only the fouling factor but also deposit thicknesses with an accuracy of +/- 5 microns, which can cause up to 10–15% heat loss depending on the nature of the biofilm and heat exchanger. The OnGuard 3B analyzer can also differentiate between biological, organic and scale deposits.

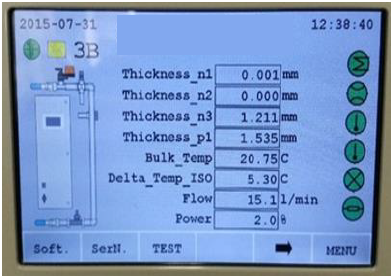

In real-world implementations, the OnGuard 3B analyzer can help facilities better manage biocide usage. Figure 3 shows the equipment’s local field human-machine interface (HMI) for settings and measurement results. Note the biofilm (Thickness_n3) measurement on the display.

Figure 3 – Human-machine interface of the OnGuard™ 3B analyzer.

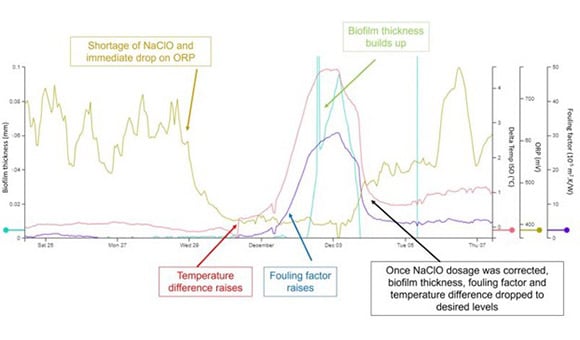

At one facility that had installed the OnGuard 3B analyzer, there was a shortage of bleach due to a logistics problem. The lack of bleach dosage created a lower oxygen-reduction potential (ORP) in a critical cooling system, which later allowed for microbiological growth to take place. As soon as the ORP level reached a critical limit, the OnGuard 3B analyzer identified an increase in both the fouling factor and temperature difference, indicating the very moment biofilm started to grow.

Aware of the issue, facility team members sought out alternate sources of bleach to supplement their supply. They adjusted the biocide dosing and continued to monitor the system. Although the biofilm continued to accumulate for a short time after the bleach dosage was corrected, all variables, including biofilm thickness, eventually returned to their normal levels. Figure 4 shows the trend graph of the cooling water system and clearly demonstrates how early, real-time biofilm measurement can improve decision-making and clarify the corrective actions to take.

Figure 4 – Trend graph showing biofilm thickness detection after NaClO shortage.

Part of a Comprehensive Biofilm Solution: ClearPointSM Biofilm Detection and Control

The OnGuard 3B analyzer is a key component of Solenis’ ClearPoint Biofilm Detection and Control program, which brings together equipment, chemistry and service to provide the only comprehensive safeguard against microbiological activity and biofilm in industrial water systems. In addition to the OnGuard 3B analyzer, Solenis offers its HexEval™ performance monitoring program to analyze heat exchanger efficiency, as well as a full portfolio of advanced chemical treatments for controlling microbiological activity and biofilm, including oxidizing biocides, non-oxidizing biocides, chlorine stabilizers and dispersants. And, of course, all of this is supported by a team of experts who understand all of the challenges your cooling systems face.

Contact a Solenis sales representative to discuss how the OnGuard 3B analyzer can be implemented in your facility to protect your assets from biofilm. In the meantime, explore these resources to learn more: