A Specialty Service Available in North America for Deep Cleaning Liquid Filling Machines and Resetting the Equipment With Industry Professionals

Maintaining a liquid filling machine can be a balancing act where the CIP system performs the routine cleaning and an OPC schedule maintains all of the non-product pathways and components to keep production running smoothly and efficiently.

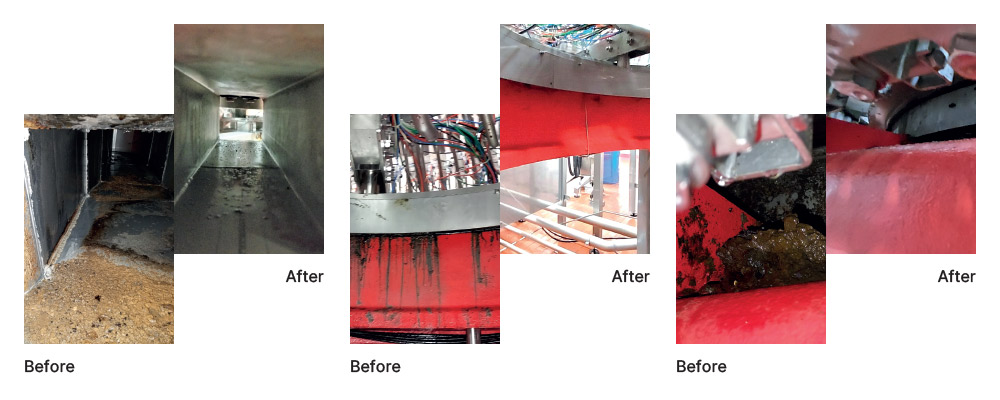

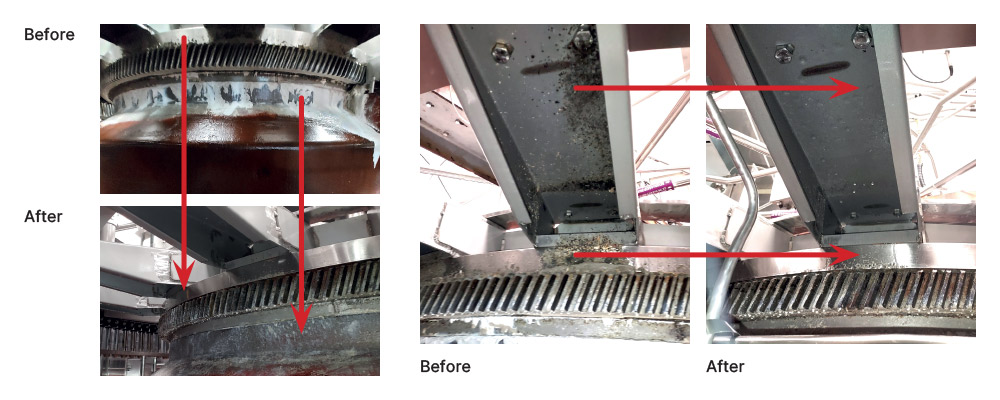

Throughout normal operation, a filler and surrounding machinery can collect excess grease, product/packaging debris, and even in severe cases mold or biofilms. That’s when the need to do a complete system reset becomes important to properly address all the items that need attention.

Figuring out when it’s time to do a deep cleaning of a machine can be a tough decision. The resetting process requires a good amount of time and typically comes with downtime to the production of products. This process in complex and companies do not always have personnel available internally to provide the expertise needed to do a reset. The disassembling and cleaning of the entire filling machine is something we specialize in and have a team of professionals to assist you and help avoid costly errors.

Our team of specialists meets with the management of the plant to determine if the filler and components can be deep cleaned. A plant visit is conducted to assess the filler and discuss the scheduling of the process as well as any possible impacts of a deep cleaning on the equipment.

As an additional option while the filler is disassembled it’s a chance to also perform any required maintenance as well as collect microbiological data. When the process is scheduled, we can also schedule our Microbiologist to travel to the plant with the team to conduct the data collection and assist in the deep cleaning reset.

The first step in our process is to break down the machine and ensure all the equipment is stripped for a cleaning foam to be applied for the recommended contact time. Heavily soiled areas are addressed and, in some cases, manually scrubbed to remove any remaining debris/contamination. The equipment is then rinsed and inspected for cleanliness. If needed an additional application of foam will be applied.

Once the OPC cleaning process is deemed complete, and the filler is reassembled a 5-Step Hot CIP process will be completed on the system. This ensures the highest levels of cleaning are achieved and that the filler is functioning at peak performance after the reset. Upon competition, Diversey will meet with plant management (if not involved with the deep clean reset process) and report any immediate concerns for food safety or other optimizations.

A final written report will be provided of the process and will include individual observations and a recommendation will be provided to repair or resolve any food safety issues or equipment issues that are identified.

FillerCheck is one solution within the Diversey Knowledge-Based Services portfolio. These services are designed to help you address food safety and operational efficiency challenges while reducing your total cost of operation.

FillerCheck is a technical, environmental, and economic evaluation to validate the efficacy and efficiency of filler and hygiene. FillerCheck will help you improve your cleaning results, maintain microbiological standards, and safeguard your food safety. Our service specialists will help you discover if your filler cleaning process is underperforming and determine which optimization actions will result in meaningful improvement.