Diversey Intelligent CIP processes and sorts CIP cleaning data so that compliance and consumption can be easily visualized and optimization opportunities uncovered.

Diversey Intelligent CIP is the plant manager's cockpit. It collects CIP cleaning data and sorts it so that it can be easily visualized to quickly review compliance against validated parameters and dig deeper to find opportunities for optimization.

Essentially, it can provide peace of mind and a documented audit trail showing that each CIP has met its targets (beneficial for GMP, HACCP, and ISO reporting).

But Intelligent CIP's real power lies in the analysis views and tools that prompt you to ask questions about why the process behaves the way it does, and more importantly, why doesn't it behave as it should?

Having up-to-date, validated cleaning protocols is a key part of a food, beverage, or dairy processor's GMP (good manufacturing processes). The protocols detail the requirements to achieve hygienically clean production lines to reduce the risk of cross-contamination. They include the cleaning parameters to make the process effective:

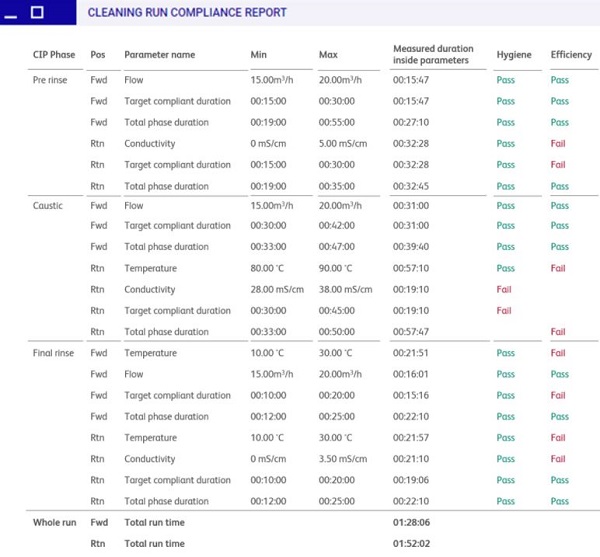

Typically, these validated parameters are programmed into the CIP automation system and then the cleaning runs are expected to behave accordingly. But how do you know if the process is always correct and meets the validated parameters every time? Enter the Intelligent CIP Compliance View and Report.

Using an intuitive traffic light system, you can quickly and easily see which CIPs meet the parameter thresholds for the expected duration and which do not. When you see a green dot, you know that the CIP was completed as per the cleaning protocol. However, if you see a red dot indicating that something did not run as expected, you can drill deeper to uncover the offending parameter(s) and what happened.