Premium Cold Washing Laundry Program - Saving up to 50% water and up to 65% energy - Up to 30% extended linen lifespan.

Clax Polar maximizes energy and water savings without compromising performance. By cold washing at approximately 30°C (86°F) and using only one rinse cycle, energy consumption is significantly reduced, while both water consumption and washing times are minimized. The lower temperature and milder washing programs help to extend the lifespan of linens.

Game Changing Technology Enables Fuel Ethanol Producers to Improve Profits

Dimension™ corn oil extraction aids enable fuel ethanol producers to significantly increase their production of corn oil—a valuable coproduct—by improving the release of oil during mechanical extraction. The extraction aids not only allow for increased corn oil production but also reduce solids in the oil, resulting in cleaner, higher-quality oil. Notably, the extraction aids have enabled many ethanol plants to produce up to 400% more corn oil, thereby improving their profit potential.

New Dry-strength Additive Allows Tissue Producers to Balance Strength and Softness

Challenged to develop a new product that would allow tissue producers to improve sheet strength without negatively affecting sheet softness, Solenis’ R&D team recently delivered a truly unique solution to the marketplace. The new dry strength additive—Hercobond™ 7550—allows tissue producers not only to improve sheet strength without affecting sheet rigidity or softness but also, in some instances, to increase productivity, to reduce energy costs, or to reduce furnish costs.

A Comprehensive Safeguard Against Biofilm in Industrial Cooling System

ClearPoint℠ biofilm detection and control program is a one-of-a-kind microbiological control service program for industrial water systems. This novel program brings together a new-to-the-world monitoring device, proprietary chemistry and expert service to provide a comprehensive safeguard against biofilm. The monitoring device employs an advanced ultrasonic probe to enable the earliest detection and most accurate measurement of biofilm growth possible.

New Antiscalants Address Challenges of Harsh Ore Processing Conditions

Scaling in ore processing circuits can negatively affect mill production and profitability. Scaling can also be difficult to control, especially under high temperature, low pH or high solids conditions. Unlike many competitive antiscalant chemistries, Solenis’ newest Zalta™ antiscalants effectively reduce scale formation even under these extreme conditions. And, when paired with Solenis’ OnGuard™ 3S analyzer, a Zalta program can be monitored remotely in real-time to verify performance.

An Advanced Solution for Predicting the Performance of Critical Heat Exchangers

Utilizing a proprietary algorithm built on data taken from thousands of heat exchangers, the HexEval™ performance monitoring program provides a diagnostic “window” into critical heat exchangers. HexEval not only monitors actual exchanger performance against design, but it also identifies exchangers that are most susceptible to scale, corrosion and fouling given current operating conditions and exchanger design.

Pergafast™ Color Developers Offer Non-phenol Alternatives to BPA for Thermal Papers

Providing thermal paper producers with a viable alternative to bisphenol A (BPA), Pergafast™ 201 is both BPA-free and non-phenolic. Pergafast™ 201 is a versatile color developer that can be used in all top-coated and non-top-coated grades of thermal paper. It produces high-quality, stable images and provides excellent resistance to heat and water, as well as oils, fats and plasticizers.

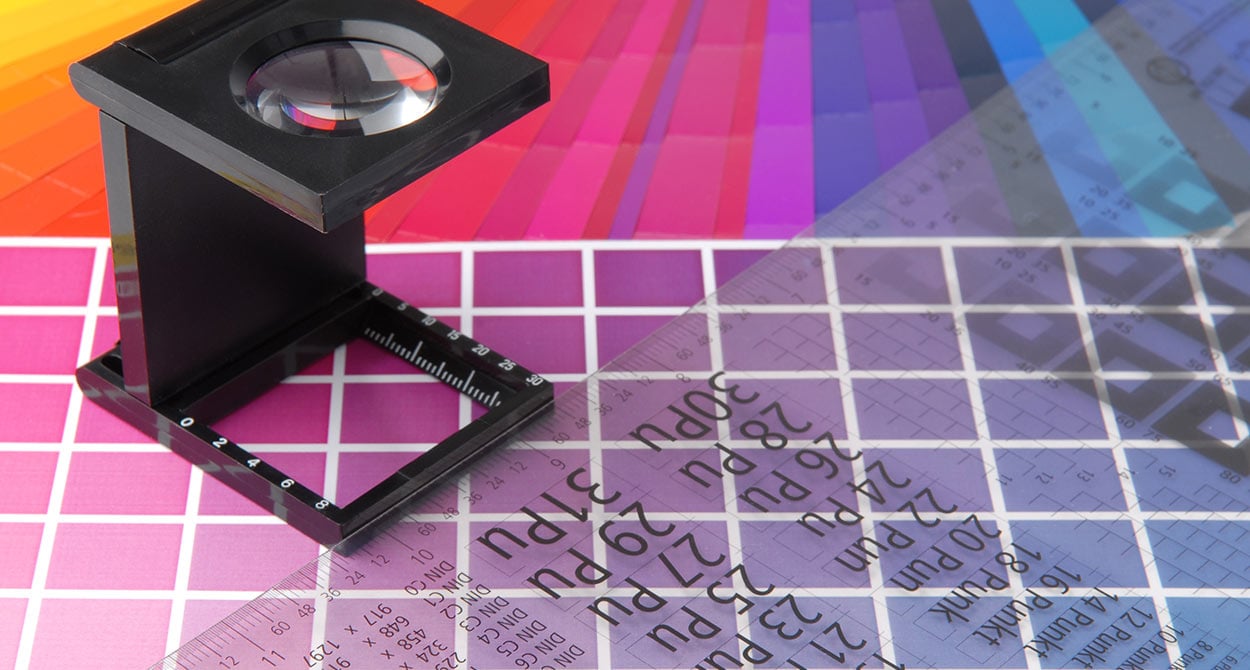

New Paper Additive Offers 3-star Rating for HP Indigo Digital Presses

Solenis’ imPress™ line of additives is up to eight times more efficient at enabling adhesion of Indigo images compared to competitive products. For papermakers already making an Indigo-grade paper or looking to diversify by quickly adding an Indigo-grade paper, imPress additives provide improved runnability and versatility. In commercial applications, a wide variety of basis weights have met Indigo adhesion targets as well as blanket compatibility targets, the other measure of 3-star qualification.