Innovative chemistries, advanced monitoring and control systems, and expert support for your food & beverage challenges.

The effectiveness of each CIP run is buried within the automation system or manually tracked through documentation. Knowing if cycles are over-using resources or have the potential to cause a contamination risk because hygiene parameters were not met, is largely unexplored.

What if you could quickly and easily see where your CIP may be causing losses and risks to your brand? What if you could analyze and compare cleaning runs to truly understand which of your processes are in control?

Diversey Intelligent CIP is a cloud-based, remote monitoring and data analysis tool for CIP (cleaning in place) data.

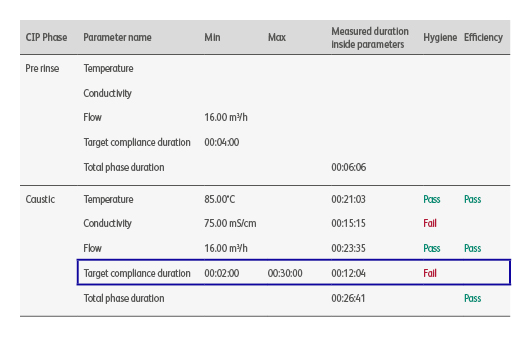

Diversey Intelligent CIP translates measured CIP data into visual, easy-to-understand, actionable information. The curtain is removed, and the details of each CIP run are discovered, providing proof of compliance and indicators of where to optimize. It brings clarity to CIP data and enables food and beverage producers to uncover the true operation of the CIP System.

The Intelligent CIP platform provides a digital history of your CIP operations and gives deeper insight and intelligence of CIP processes beyond compliance.

An in-depth analysis service for F&B CIP systems. Includes hygienic design and cleaning chemistry evaluation for food safety effectiveness and CIP optimization.

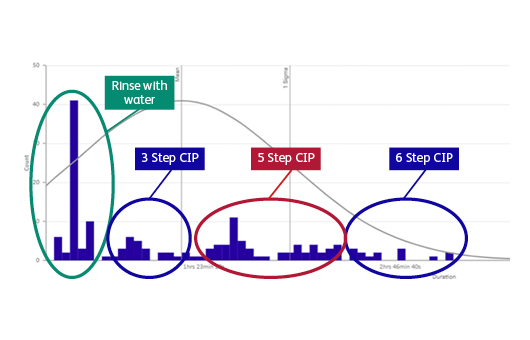

Learn MoreAre your CIP cycles over or under cleaning? CIPTEC uses sensors and data analysis to calculate the effective and ineffective wash times to a six-sigma safety margin.

Learn MoreBlog Article

Intelligent CIP’s tools transform how you see your CIP, securely and remotely processing your CIP data and shining a light deep into your automation system.

Blog Article

[ON-DEMAND WEBINAR] The future of product quality and continuous improvement is inevitably linked to digitalization. Find out how to enhance human expert-based assessments to data-driven decision making.

Blog Article

[ON-DEMAND WEBINAR] Discussing the importance of hygienic design, trends and technologies and Diversey's unique approach to CIP system design.

The Diversey team offers the right people, technology and expertise to solve your most complex food and beverage challenges.